The company Mars announced the instigation of a multi-year partnership with the logistics leader DHL. This landmark project saw the construction of two state-of-the-art warehousing facilities with a world-class logistics operation.

Mars UK transport over 1.2 million pallets of their products every year – if you were to stack these pallets on top of each other, it would represent the equivalent of shipping the height of Mount Everest every other day. The new logistics operation was to remove 7.7% of the existing Mars transport from the roads, equivalent to a million miles a year, or 8,547 times around the M25.

Capital Compactors were appointed to provide the waste and recycling equipment designs and solutions so that the fast processing and automation of materials on site could be maintained and improved. This was to be a fully customised and personalised resolution that would be in keeping with the desire to ensure that the reduction in the impact on the environment and the proposed annual carbon savings could be met.

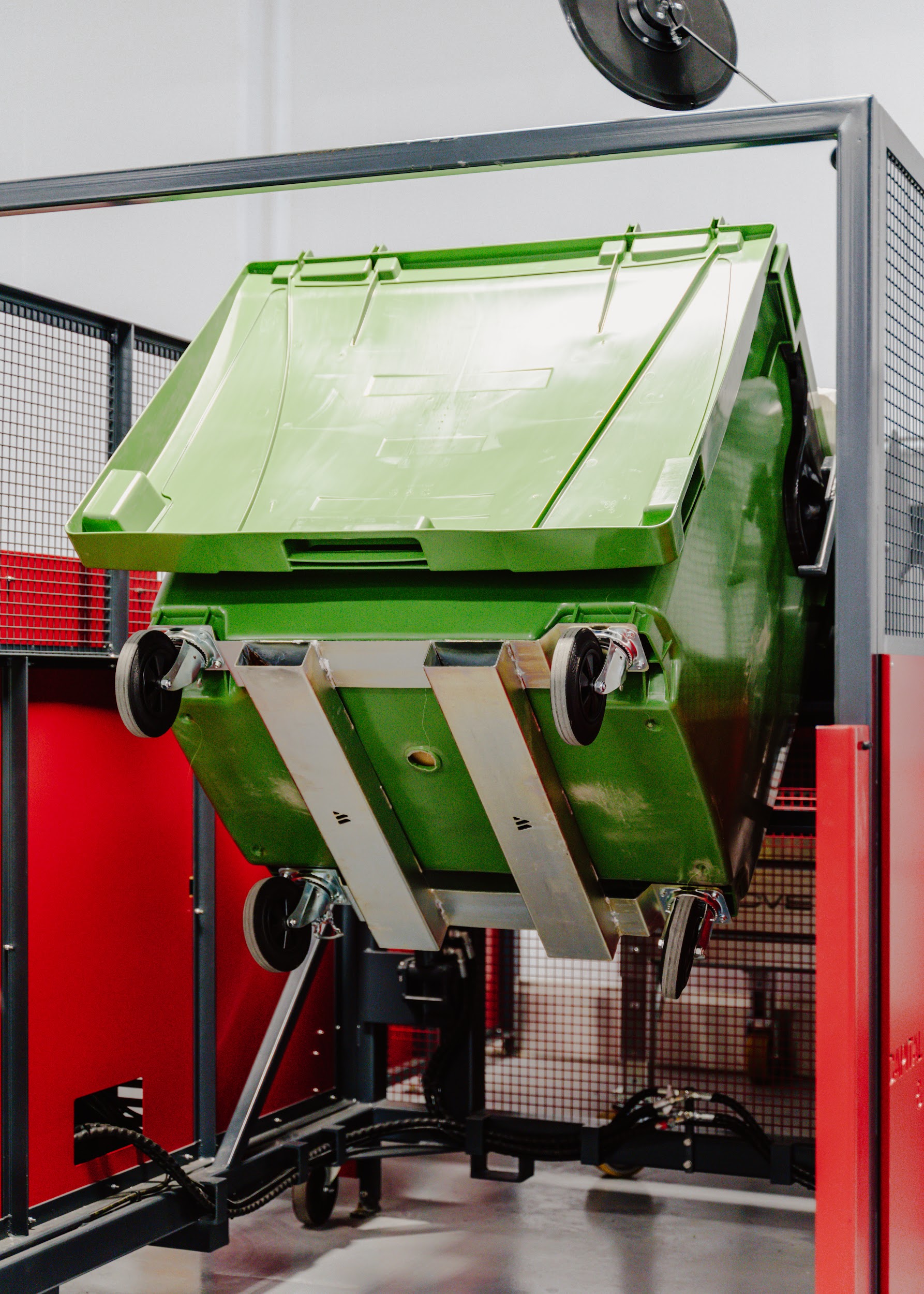

As part of the project, we designed, built and delivered an external build chute, fully automatic baler, conveyors, bin lift, and external canopy to protect the equipment placed outside.

The whole system was built efficiently to process large volumes of cardboard within a food packaging business. External loading chute feeding a fully automatic baler on the ground floor.

Ground floor gantry system and conveyor feeding from another internal conveyor and material from the chute fed material on floors one and two.

Ground floor internal conveyor feed

First-floor feed using 1100ltr bins via our built bin lift

Minimal handling of cardboard using the 1100ltr bins

Ground floor conveyor feed for easy hand loading of cardboard in the warehouse section of this site.

The fully automatic is kept out of the weather conditions by adding a canopy. It also provides suitable working conditions for the operatives.

Easy-to-use equipment with modern and safe electronic safety systems.

Perfect, stackable, mill size bales produced in the APK E55 baler.